Jaw-Dropping Offers: Discovering the very best Jaw Crushers for Sale Online

Jaw-Dropping Offers: Discovering the very best Jaw Crushers for Sale Online

Blog Article

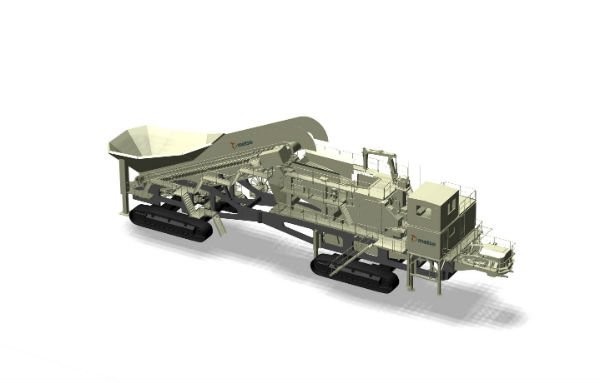

Effectively Reuse Materials With the Power of a Jaw Crusher

One such solution is the use of a jaw crusher, an effective maker that has actually revolutionized the recycling process. In this conversation, we will certainly delve right into the benefits of a jaw crusher, the materials ideal for crushing, the considerations for reusing operations, and valuable maintenance and safety and security tips. Let us discover exactly how a jaw crusher can play a critical duty in successfully reusing materials.

Benefits of a Jaw Crusher

The advantages of a jaw crusher are countless and make it an important device for reliable recycling of products. The jaw crusher's style permits for large items of material to be crushed down to a smaller dimension, resulting in a much more convenient and uniform item.

One more benefit of a jaw crusher is its high capability. jaw crushers for sale. These devices are designed to handle huge amounts of product, enabling for effective handling and increased productivity. This is specifically vital in reusing procedures, where large amounts of material need to be processed promptly

Materials Ideal for Squashing

Numerous products are ideal for squashing in a jaw crusher, relying on their physical residential properties and make-up. Jaw crushers are versatile makers that are commonly utilized in demolition, mining, and building industries to squash materials into smaller sized dimensions. Among the essential elements in determining the suitability of a product for crushing is its firmness. More challenging materials such as quartz, granite, and basalt are often squashed in jaw crushers because of their high compressive stamina. These products can stand up to the stress exerted by the jaws of the crusher, causing effective squashing.

An additional vital consideration is the abrasiveness of the product. Products such as sedimentary rock, dolomite, and sandstone are known to be unpleasant and can create extreme wear on the jaws of the crusher. With appropriate upkeep and the usage of wear-resistant materials for the jaw plates, these products can still be efficiently crushed.

Additionally, the shapes and size of the material also play a role in identifying its viability for squashing. Jaw crushers are especially reliable in crushing huge, tough, and irregularly shaped materials. They might not be as reliable in squashing smaller sized, softer, and much more uniform materials.

Recycling Operation Factors To Consider

When thinking about recycling procedures, there are a number of vital elements to think about. Firstly, it is necessary to analyze the kind and quantity of products that will certainly be refined. This will certainly determine the dimension and ability needs of the jaw crusher that will certainly be used in the reusing operation. In addition, it is crucial to consider the desired final result dimension. Different crushers have various abilities in terms of decreasing materials to a specific size variety. Comprehending the end product published here requirements is essential read this in picking the suitable jaw crusher for the recycling procedure.

Another important consideration is the functional expense of the recycling operation. This consists of the price of obtaining and keeping the jaw crusher, in addition to the price of electrical energy and other resources required for its procedure. It is necessary to select a jaw crusher that offers high performance and reduced operating prices to make certain the productivity of the recycling operation.

.png)

Maintenance and Security Tips

Considering the essential nature of maintenance and safety and security in a reusing procedure, it is vital to carry out reliable methods to ensure the smooth performance of the jaw crusher and secure the health of personnel entailed. Normal upkeep is vital for the jaw crusher to operate at its peak efficiency.

Additionally, security preventative measures have to be purely abided by in order to prevent injuries and mishaps. All employees operating the jaw crusher must receive correct training on its use and safety procedures. Safety equipment, such as construction hats, shatterproof glass, and ear protection, need to be worn in any way times. The workplace should be kept complimentary and clean of particles, and any possible dangers ought to be resolved right away.

Normal assessments see it here and maintenance timetables must be established to guarantee that the jaw crusher is functioning ideally and securely. By adhering to these maintenance and safety and security ideas, recycling procedures can take full advantage of the performance of their jaw crushers while focusing on the well-being of their workers.

Making Best Use Of Effectiveness With a Jaw Crusher

To maximize the performance of a jaw crusher, it is necessary to apply effective strategies and strategies. Among the vital techniques is to make sure correct feed control. This involves keeping a constant and controlled feed rate to the crusher, which assists to avoid overloading and maximize throughput. Additionally, the size and kind of feed product ought to be thoroughly thought about. It is crucial to match the jaw crusher's capabilities to the specific requirements of the material being refined. Changing the jaw crusher's shut side setting (CSS) can additionally play a considerable function in making best use of performance. The CSS is the tiniest range in between the jaw plates throughout the squashing process. By changing the CSS, the size of the item can be regulated, resulting in better bit form and dimension distribution. Routine maintenance and assessments are vital for ensuring optimal performance and maximum efficiency. This includes checking and changing used parts, lubricating the crusher regularly, and keeping the crusher tidy. Keeping track of the crusher's performance via regular measurements and information evaluation can help recognize opportunities for renovation and optimize the crusher's operation. By executing these techniques and strategies, operators can take full advantage of the efficiency of a jaw crusher and attain much better general productivity in their reusing operations.

Conclusion

In this discussion, we will certainly dive into the advantages of a jaw crusher, the products ideal for squashing, the considerations for recycling operations, and valuable upkeep and safety suggestions. Let us explore exactly how a jaw crusher can play a crucial function in efficiently reusing materials.

Checking the crusher's efficiency through routine dimensions and information analysis can aid identify possibilities for improvement and maximize the crusher's procedure.In final thought, a jaw crusher supplies numerous benefits in successfully recycling products. On the whole, the usage of a jaw crusher proves to be an effective option for recycling materials.

Report this page